Panch Hatdi, Porbandar, Gujarat

- GST NO. : 24AAGCM9165R1ZN

100 Kilogram (MOQ)

| Business Type | Manufacturer, Exporter, Trader, Importer |

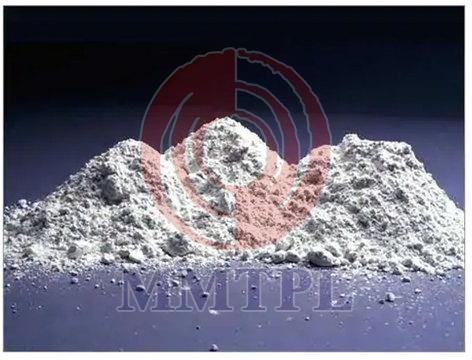

| Color | Off White |

| Alumina Percentage | 40% to 45 % |

| Form | Powder |

| Click to view more | |

Product Details

We are proud to introduce ourselves as the foremost Heat Resistant Fire Cement Manufacturer from India. We supply Fire Cement that is used for stopping surfaces, laying pointing surfaces, filling up cavities, repairing baffles etc. In addition to this, it is used for laying fire in silica bricks, insulating bricks and high alumina bricks. Firebrick Cement offered by us is available in varying quantities suiting to the specific requirements of the customers. Moreover, we ensure time bound and safe delivery of fire cement to the set destination.

Why To Use : 'Firetech' Fire Cement:

- It is air-setting i.e. It sets hard at room temperature.

- It's strength goes on increasing with rising temperature.

- It reduces furnace troubles and ensures much longer life.

- It welds each brick to the other thus making each joint a perfect joint.

- It has twenty four times higher strength compared to fire clay/ mortars.

- It reduce haircracks, increase workability and higher strength after setting.

- It protects fire brick lining against corrosive action of slags, gases and ashes.

- It is extremely volume stable, hence it does not shrink on drying or on being heated.

- It makes the furnace, gas and air tight, to ensure higher thermal efficiency of furnaces.

- It gives thin, compact brick to brick joint and makes the whole masonry work one solid piece.

- It ensures perfect refractory lining with comparative ease, quickness and perfect workmanship.

200 KGS. of fire cement is required for 1000 standard fire bricks (9"x41/2x3") for laying.

Physical & Chemical Property

| Refractoriness | 15500C-16000C | Sintering Temperature | 18000C |

| Density | 2200 Kg. / m3 | Service Temperature | 15000C |

| Shrinkage | Nelligible | Grain size | 0-0.5 mm. |

| Initial Setting Time | 2 Hours | AL2O3 | 55-60 % |

| Final Setting Time | 6 to 8 Hours | SiO2 | 35-40 % |

| Type of Bonding | Chemical and Ceramic | Fe2O3 | 2.5 % |

| Type of Setting | Air and Heat Setting | Packing (a)Cement (b)Liquid |

50 Kgs. HDPE Bags 25 Kgs. Drums |

Looking for "Fire Cement" ?

Explore More Products